Butadiene Styrene Co-polymer

A new generation of brominated flame retardants: Butadiene Styrene Co-polymer

An innovative brominated polymeric flame retardant (FR) has been developed as an alternative to HBCD to provide effective flame retardant performance in polystyrene foams such as Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS).

These foams, commonly used in building and construction, ensure that homes, offices and public buildings are energy efficient and comfortable, whilst meeting fire safety requirements.

Primary benefits of brominated flame-retardants in foam insulation:

Reduced likehood of ignition

Slower fire growth

Reduced heat release

Lower % by mass of flame retardant

BUTADIENE STYRENE COPOLYMER

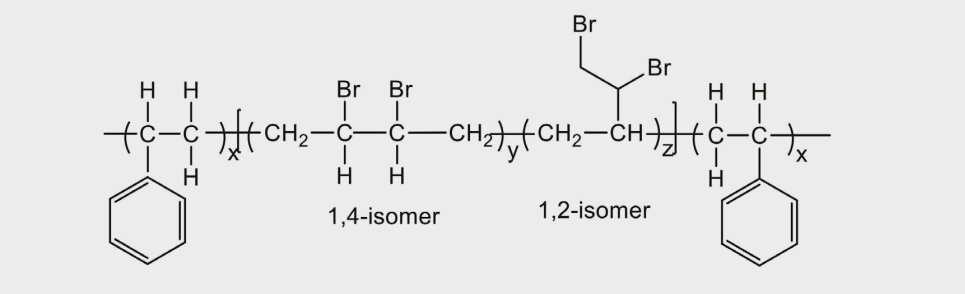

The new brominated polymer flame retardant is based on a co-polymer of styrene and butadiene where the polybutadiene portion is brominated on to the 1,2 and 1,4 isomer units to give a brominated polybutadiene. This flame retardant exhibits a superior environmental profile to that of HBCD – being stable, with a high molecular weight. It is also classified as a nonhazardous polymer and as a Polymer of Low Concern

(PLC) with officially recognised environment, health & safety characteristics (see figure 1). Polymeric flame retardants, generally speaking, are inherently sustainable substances. Their high molecular weight makes them unlikely to penetrate through the cell membranes of living tissues. They are therefore not likely to be bioavailable and to bioaccumulate in the food chain.

HAZARD SUMMARY FOR HBCD AND ALTERNATIVES

The table below is reproduced from the USEPA 2014 report:2

This table contains hazard information for each chemical; evaluation of risk considers both hazard and exposure. Variations in end-of-life processes or degradation and combustion by-products are discussed in the report but not addressed directly in the hazard profiles. The caveats listed below must be taken into account when interpreting the information in the table. VL= Very Low hazzard L=Low hazzard M=Moderate hazzard H=High hazzard VH=Very high hazzard – Endpoints in colored text (VL, L, M, H, and VH) were assigned based on empirical data. Endpoints in black italics (VL, L, M, H, and VH) were assigned using values from predictive models and/or professional judgment. d This hazard designation would be assigned MODERATE for a potential for lung overloading if >5% of the particles are in the respirable range as a result of dust forming operations § Based on analogy to experimental data for a structurally similar compound. ¥ Aquatic toxicity: EPA/DfE criteria are based in large part upon water column exposures which may not be adequate for poorly soluble substances such as many flame retardants that may partition to sediment and particulates.

DEVELOPING AN ALTERNATIVE TO HBCD

As HBCD is being phased out globally, manufacturers of thermal insulation foams now have a more sustainable alternative flame retardant.

In response to the identification of HBCD as meeting the criteria for classification as a persistent, bioaccumulative and toxic (PBT) substance in the EU, industry embarked on a search for a feasible technical alternative. This alternative would not only need to meet requirements in terms of flame retardant efficacy, but would also need to be environmentally superior and more sustainable. The criteria for such an innovative technology are indicated in figure 1. After an intensive research and development exercise, the industry commercialized the new brominated polymeric flame retardant.

CRITERIA FOR A NEW FLAME RETARDANT FOR POLYSTYRENE FOAM TO REPLACE HBCD

For polystyrene foam applications where HBCD was used, several conceptual elements were combined to meet existing fire safety and use requirements, including an improved environmental & health toxicity profile to comply with regulatory guidelines.

FLAME RETARDANT PERFORMANCE

FLAME RETARDANT PERFORMANCE

4 Meet flammability requirements in foam globally (e.g. EU, JP, NA, CN, KR)

ECONOMICALLY VIABLE

ECONOMICALLY VIABLE

4 Acceptable cost, commercially available

BUTADIENE STYRENE BROMINATED CO-POLYMER – INHERENTLY MORE SUSTAINABLE

In 2014, the US Environmental Protection Agency (USEPA) reviewed the environmental and hazard profile of the new polymeric alternative to HBCD and concluded:

“The hazard profile of the butadiene styrene brominated copolymer shows that this chemical is anticipated to be safer than HBCD. Due its large size, lack of low molecular weight (MW) components, and un-reactive functional groups, human health and ecotoxicity hazard for this copolymer are measured or predicted to be low.”

3 EPA, 2014. Flame Retardant Alternatives to Hexabromocyclododecane (HBCD). USEPA Design for the Environment

Final Report June 12, 2014, http://www.epa.gov/sites/production/files/2014-06/documents/hbcd_report.pdf/

FROM A HEALTH AND ENVIRONMENTAL STAND POINT, IT IS NOT A CONCERN FOR MAMMALS NOR IS IT A PBT

HEALTH

Not of concern for mammals

Not genotoxic

Not acutely toxic

Not sub-chronically toxic

Not developmentally toxic

ENVIRONMENT

Not a PBT – Persistent, bioaccumulative and toxic substance

Persistent by design

Not bio-accumulative – large molecule, not likely to be transported through cell membranes

Not toxic – below ecological toxicity concern levels

ENVIRONMENTAL, HEALTH & SAFETY (EH&S)

ENVIRONMENTAL, HEALTH & SAFETY (EH&S) SUITABLE FOR DIFFERENT PROCESSES

SUITABLE FOR DIFFERENT PROCESSES EFFECTIVE FOAM PERFORMANCE

EFFECTIVE FOAM PERFORMANCE